NEW BALANCE

RUNNING AND TRAIL 2005 - 2007

After taking a season off to snowboard in Lake Tahoe, I took a job with New Balance in Boston/Lawrence. It was a sharp shift to go from a small team in Hermosa Beach to a large multi-billion dollar shoe machine and from thousands of units to millions. I was surrounded by talented designers and developers who breathed footwear and sneaker culture. A few examples of the shoes I worked on worth noting are below.

Conceptualized and implemented an internal, grass-roots rebranding movement called “One More” that unified multiple divisions, provided employees a forum with the executives to discuss brand misrepresentation, and led to the 2007 rebranding of New Balance and the creation of the Associate Engagement program.

Created the New Balance sole technology “N-Fuse”, a patented cushioning solution for the big-box market aimed to have high visual impact at a low price point; selling more than 10M pairs, contributing more than $500M to revenue.

Analyzed market trends and evolving fashion profiles while working with Asian vendors to develop cost sensitive solutions to complex shoe constructions and lasting design, material, and process strategies

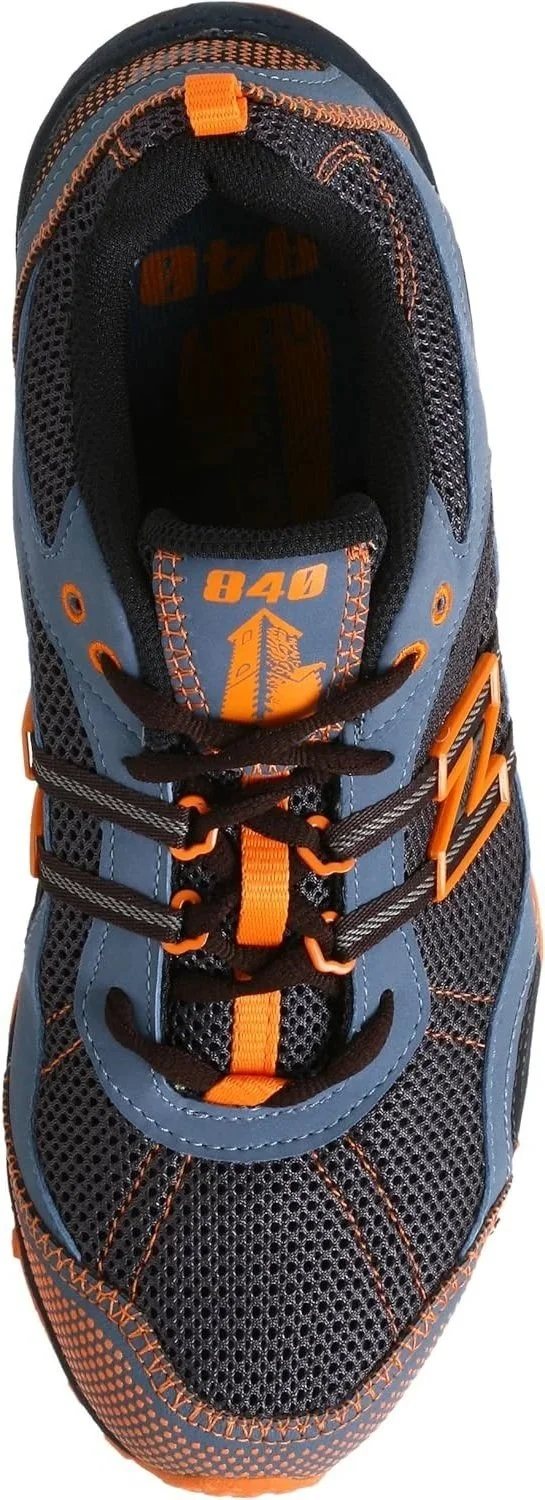

801 FELL RUNNER

The 801 (840) Trail shoe was to be a more structural brother to the phenomenally successful 790 trail shoe designed by Chris Wawrousick. It was to be a $16 FOB that retailed for $80, and inspired by the UK’s sport of Fell Running.

The project was maybe one of my favorite ones while at NB because the trail market provided a lot of room to expand and play with features, imagery, textures, materials, and iconography.

The final design connected the two clocktowers of both the Lawrence, MA New Balance design headquarters, and the Moot Hall clock tower in the UK where famous Fell running event, the Bob Graham Round, starts and ends.

Other imagery in teh shoe were morse code bits on the tongue and counter as well as utilizing a protective hexagonal TPU print on the toe cap that gradually comes together as a solid shape to protect the big toe on the medial side.

Lastly, the show permitted an opportunity to design a significantly more structural medial side compared to the lateral side.

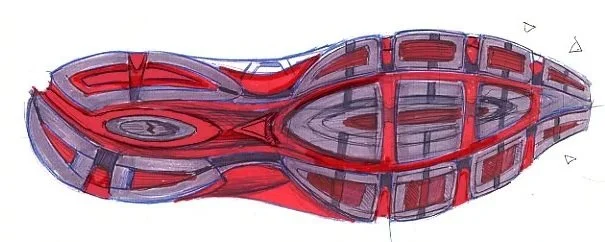

THE 770

EARLY 00’s MAXIMALISM

The 770 (725) was an incredible shoe to work on. It was a time of peak maximalism with patterns and overlays, and this shoe was a distinct example of doing everything all at once, from TPU parts, to complex prints, to transparent and translucent materials. The 770 was a last gasp of complexity before fashion took a hard swing to minimalism.

A $24 FOB shoe to retail for $80, but with the permission to “make it look unlike a running shoe”.

For the sole unit, the direction was to keep the Abzorb heel piece but design something more engaging around it with a distinctly different lateral and medial side. This was achieved by bringing the outsole up into the midsole and using the color shift as a way to draw the eye.

After going through a few different early sketches, we decided a layered saddle story would be a strong visual style for this shoe, and we’d use a screen printed upper with a layer of translucent mesh on top of a TPU printed saddle. Between the screen printed upper and the TPU print, we used connective straps to further illustrate the saddle support.

The final shoe after multiple tape-ups and pull overs was a complex layered, stenciled, and overlayed monster that captured the maximal feel of the mid 00’s with all the shine and plastic of the era.

Looking back, Scott Rigolini (the incredible developer) and I did too much, we went too far, we danced too close to the plastic overlay sun, but the project was absolutely, enormously fun.

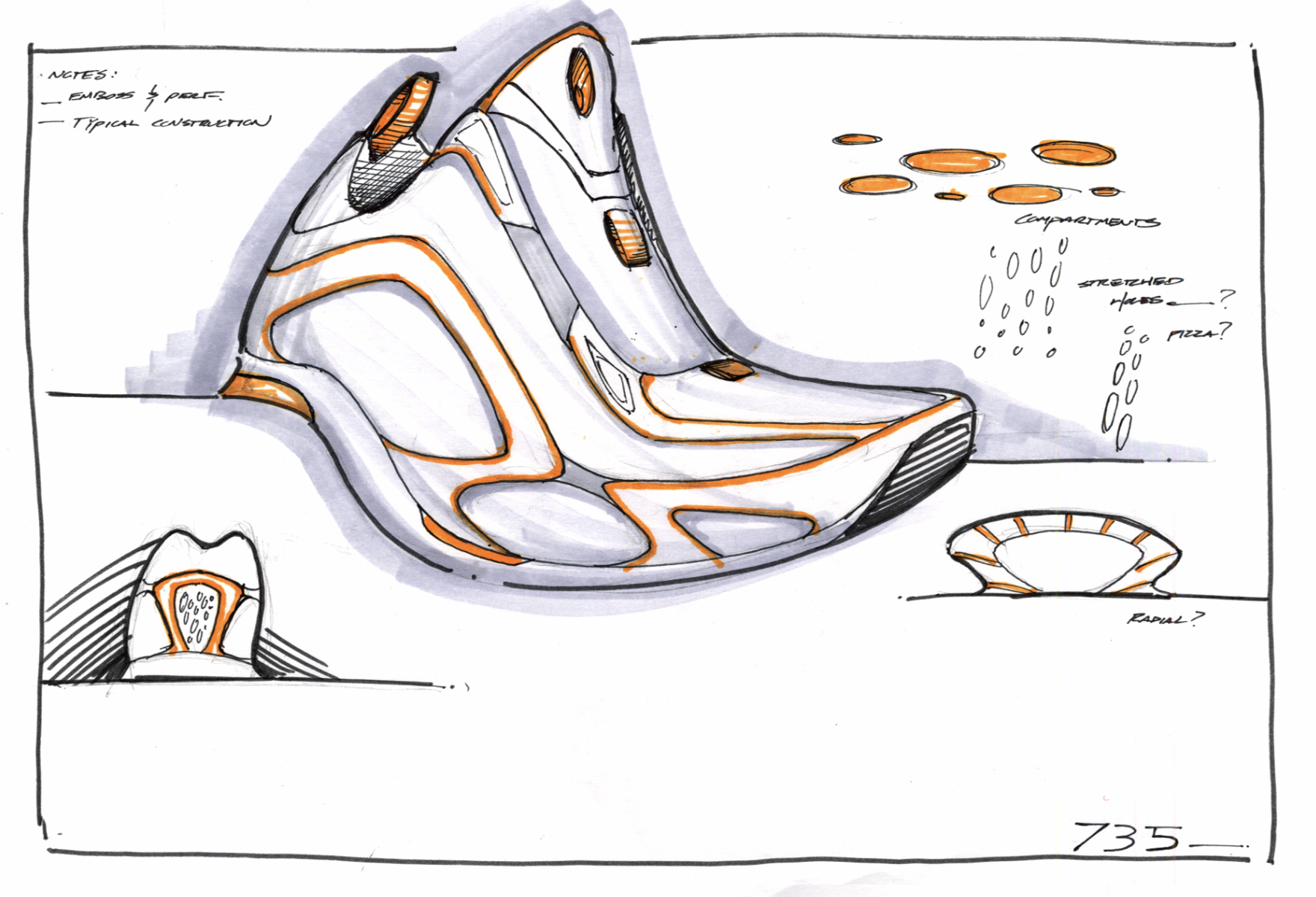

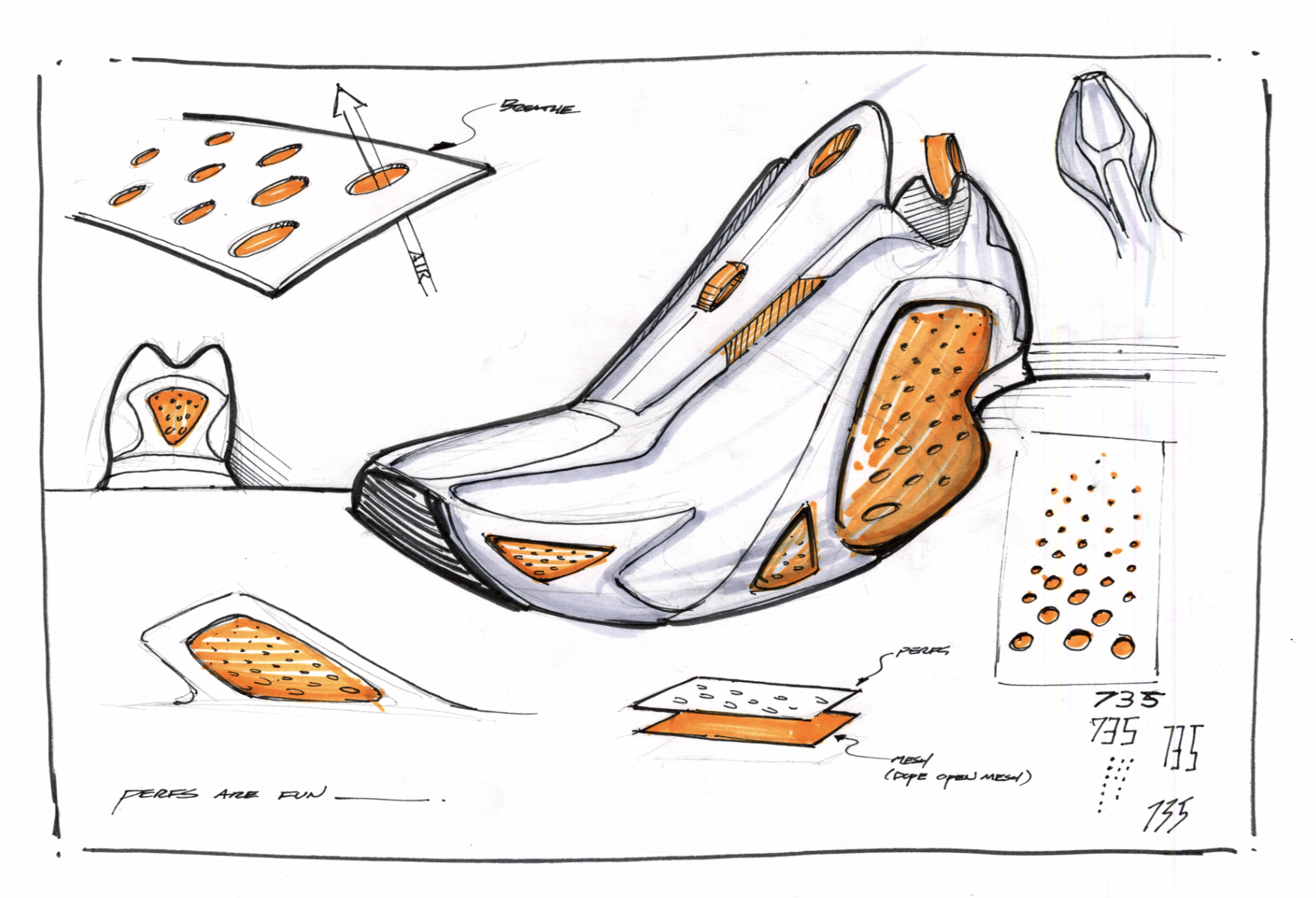

735 NEUTRAL CUSHIONING

I NEVER GOT TO KNOW YOU

One of my last running shoes for our market, the 735 was a $21 FOB shoe to retail for $75 where I was tasked to create a new upper for a current midsole.

The final design layered mesh and webbing in the saddle with an external synthetic “cage” to look like gills or vents. The shark-like aesthetic was continued with angular, “teeth” element throughout the shoe.

The project met an early grave for the unique-to-me reason that it looked better than a $120 shoe that we were launching at the same time. Because of the risk of cannibalization, it never made it to market. I still think this design and approach indicated my maturity in understanding the classic, noisy, layered running shoe style.

8507 ZIP

AN EXERCISE IN SOLE UNIT PRICE INFLUENCE

The 8507 was the 2nd entry for New Balance in the Zip sole unit technology like. The unique, molded heel was designed to take on technologies like Nike Shox. The Zip sole unit, however, was heavy because of the materials and expensive because of the complex molding process, leaving very little in the way for an upper.

One of the ways to solve this was to use a die-cut perf pattern and EM weld for the upper combined with a back painted, clear TPU saddle to give the show a sense of value while also conveying a more innovative, unlayered approach to the upper. Julie Belkus was my developer/evangelist on this that truly found a way to make the upper happen when New Balance hadn’t done anything like this before with HF welded perfs or such large pieces.

645 N-FUSE

DUAL DENSITY SOLE UNIT — STACK EM UP FOR VALUE

The 645 was one of the most fun projects and shoes I got to work on. The challenge/charge was to evolve the 644 sole unit using a more aggressive and sculpted combination of midsoles to tell a better story to the consumer as well as convey a higher level of value than other shoes in the space.

I worked with the engineering team to overcome some of the issues with a stacked midsole in the past, and we were able to do amazing things with the draft angles and construction of the midsoles to nest the top one properly while also creating windows into the other midsole. It was a visually impressive sole unit at an extremely low price point.

The upper was a simple construction with few overlays and a TPU saddle meant to look like water splashed from the forefoot.

In production, this was also a 1MM pair shoe. It was one of the projects I didn’t want to leave behind because the potential for the dynamic, dual sole units felt untapped. I had other sketches and ideas I wanted to try. Even now (2025), I see what On is doing and think that New Balance could have beaten them to market with a unique sole unit and upper story at On’s prices.

644 DUAL MIDSOLE

FULL LENGTH N-FUSE

The 644 was my first full shoe with New Balance, and it really shows. I was new to athletic footwear, and the price points really restricted what was possible from a material and construction standpoint. The product was initiated to be a $65 shoe that had a $16 FOB.

The goal was to take the dual density midsole story from other shoes and extend it from the heel to the whole foot. While this created some really great design opportunities for a fluid and graceful pairing with the dual midsoles, the engineering team had a tough time adapting it to manufacturing — a problem later overcome with the 645. This led to a stacked, sandwich look to the shoe that communicated the presence of the dual density foams, but didn’t convey the level speed or performance that I was hoping for in the initial sketches on the seen below.

The 644 went on to sell 1MM pairs, hitting the market at the right time.

The 1510

COMING SOON

Another example of mid-00’s over bedazzling. :)